Things you should know when buying valves

Valves are essential to control flow & pressure in processing plants. Before starting the valve selection, it is important to have basic information about it such as types and sizes available, the material of construction, maintenance, and performance requirements. Choosing the right valve can be a daunting and time-consuming process. If you have basic knowledge it will make it easier to find the right type of valve according to your requirements. Here are some points that will help to choose the most suitable valve.

- Media flowing- Media flowing through the pipeline largely impact valve selection. Valves are constructed with different configurations and technology for each application. For example, to regulate the flow of granules or bulk materials solid valves are required while controlling the flow of liquid necessitates a liquid or hydraulic valve.

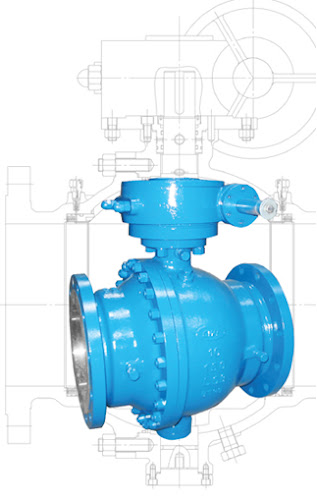

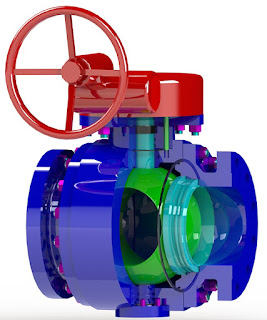

- Size and Material of construction- Proper sizing of valve is also important. Common types of valves are ball valves, gate valves, butterfly valves, needle valves, globe valves, etc. All valves are constructed in small and large sizes with different metal, the size and material need to be compatible with fluid flowing through it.

- Performance and Maintenance requirements- It is also important to determine the performance requirements. If you need valves to regulate the flow of pressurized gases, metal valves can be the best choice because they tend to be stronger than plastic valves. It is also important to consider ongoing maintenance requirements.

- Manufacturer identification- Identify the manufacturer who has a long history of providing valves to industry in your local area. A good example of this is the CWT valve which is progressive supplier of API 6D ball valve in Canada. Make sure to purchase from a reliable manufacturer that follows safety standards while manufacturing.

To get the type of

valve you are looking for visit http://cwtvalve.com/

Comments

Post a Comment