All you need to know about ball valves

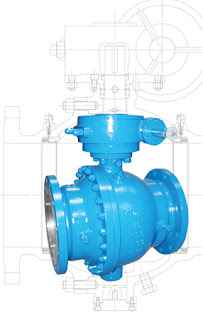

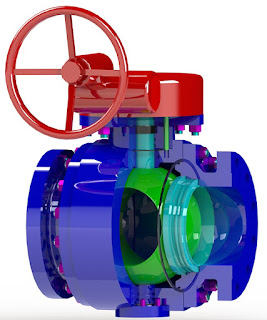

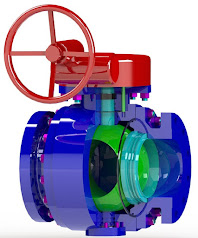

Ball valves are widely used in industrial machinery and equipments. There are many types of valves designed for specific use and one of them is ball valve which is extensively used in industries, its application is found in petrochemical industries, power plants, food processing industry, waste water management, pharmaceutical, and many more. They are available in different sizes but the construction is same, cylindrical in design with a ball in the middle to control the flow of material flowing through it. The opening and closing of the valve is solely controlled by the middle ball.

- Ball valves are lightweight, can be easily installed and operated with too much labor and skill, there is no need of an expert professional to operate these valves. They are convenient and safe in usage because of their simple design and mechanism.

- These valves are highly efficient with excellent functionality. They can control and regulate both high pressure and low pressure flow of liquid and gases effectively. The risks of leakage are minimum using ball valve due to its excellent sealing capability.

- Ball valves are less prone to wear and tear, that’s why they do not need frequent maintenance as compared to other types of valves. If needed, they can be repaired easily due to its simple mechanism.

- Ball valves can withstand in extreme pressure and temperature conditions, making it one of the strongest valve type. Additionally, they are less prone to rust or corrosion because of the resistive properties of material it is made of.

- The cost of these valves is reasonable and can be easily afforded. They are cost-efficient option in term of both price and maintenance.

Looking for a manufacturer to purchase high quality valves at reasonable prices, visit http://cwtvalve.com/

Comments

Post a Comment